Rotary Rack Oven : MDF 200

Technicial Specifications

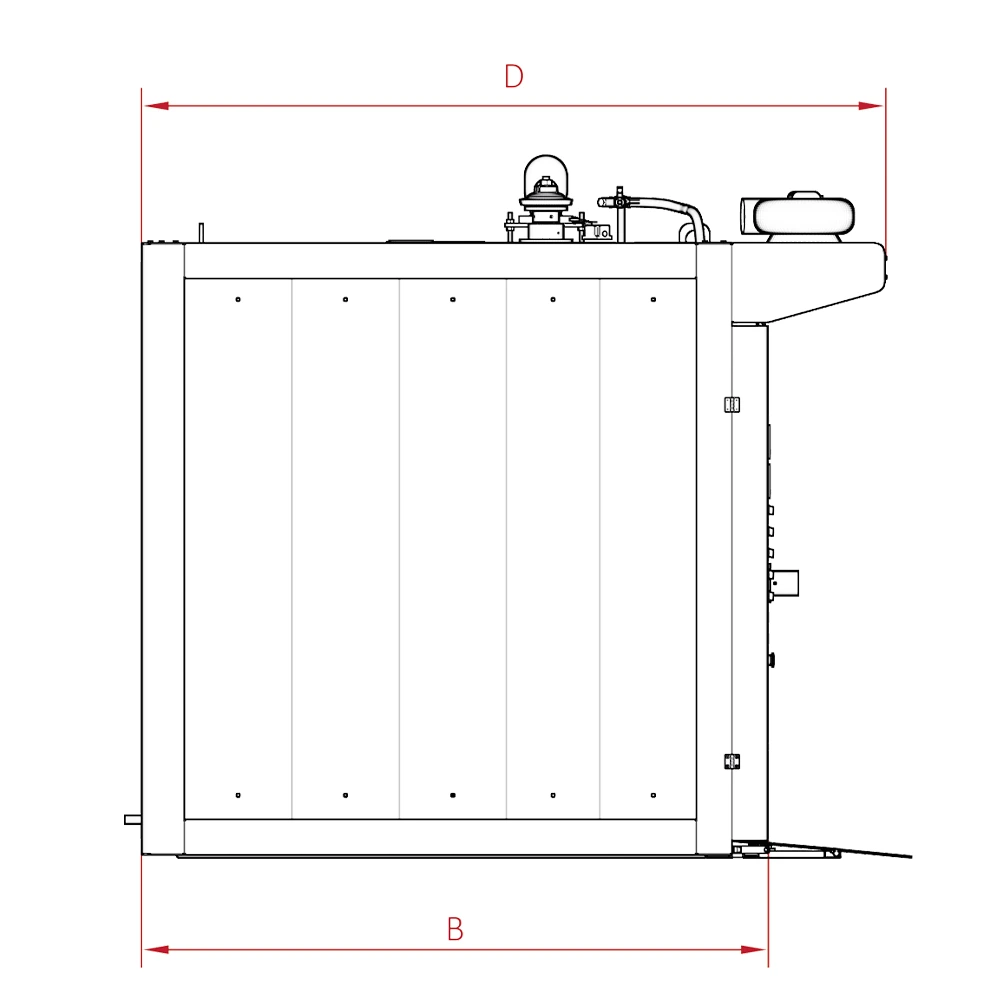

Below, you can find all the technical specifications of the MDF 150 rotating rack oven model:

| Model | Unit | MDF 200 | |

| Capacity* 8 h/dough |

kg | 2150 | |

| Baking surface | m2 | 11,2-14,4 | |

| Number of trays | adet | 14-18 | |

| Tray size | mm | 750×1040-740×980 800×1000 |

|

| Distance between trays | mm | 114-90 | |

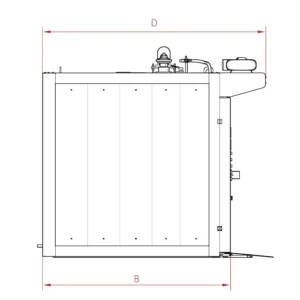

| Width(W) | mm | 1600 | |

| Length (L) | mm | 2350 | |

| Height (H) | mm | 2250 | |

| Electrical power | Kw | 3.5 | |

| Heating capacity | kcal / saat | 70000 | |

| Gas coupling pressure | mbar | 50 | |

| Source of energy | Diesel, Naturel Gas Or LPG | ||

| Weight of oven | kg | 1750 | |

| Control system | Manual, Digital and PLC | ||

| Consumption** | Diesel (lt/h) |

8 | |

| Natural Gas (m3/h) |

9.2 | ||

| LPG (lt/h) |

6.8 | ||

| *The capacity shall vary according to the weight and baking time of the product |

| * Energy consumption under normal conditions |

| The manufacturer reserves the right to change specifications without prior notice. |

A rotary rack oven is a crucial piece of equipment in commercial bakeries and food production facilities, providing efficient and uniform baking of a wide range of products. Let’s explore the intricate details and functionalities of rotary rack ovens:

MDF 200 Rotary Rack Oven Video:

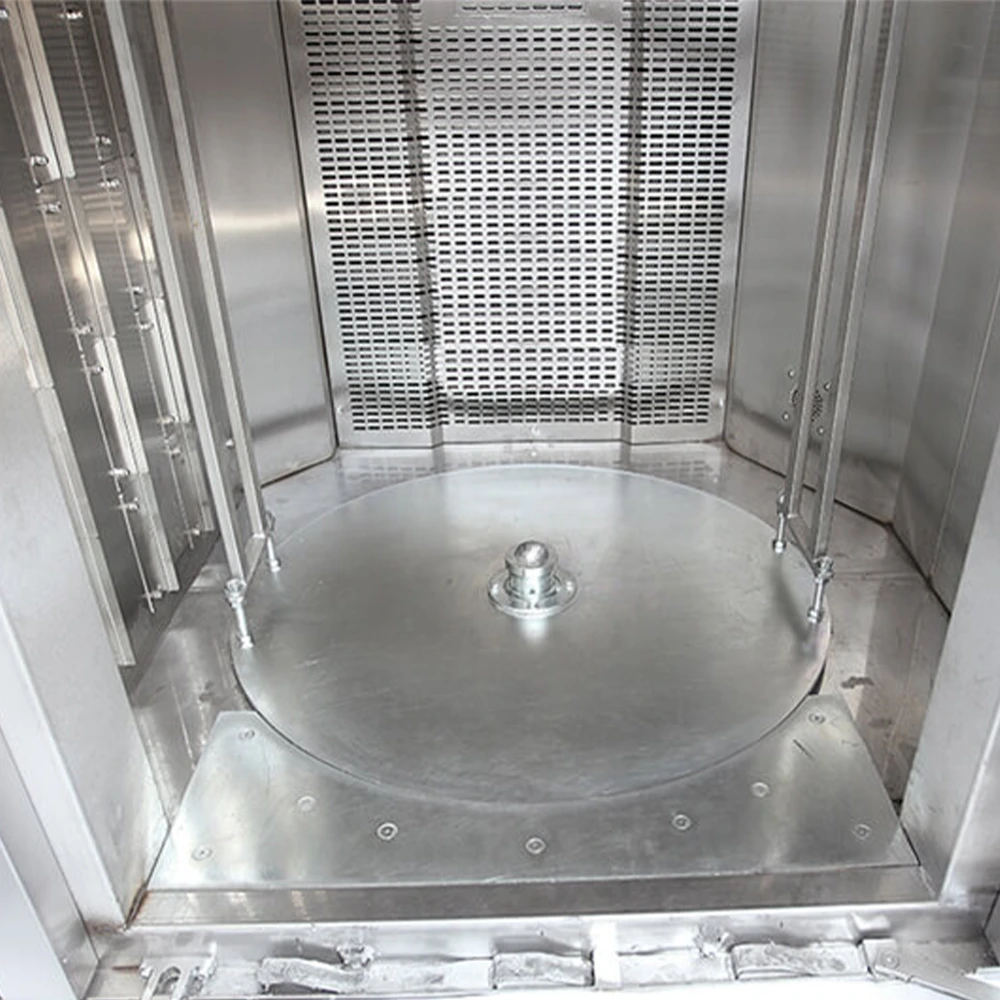

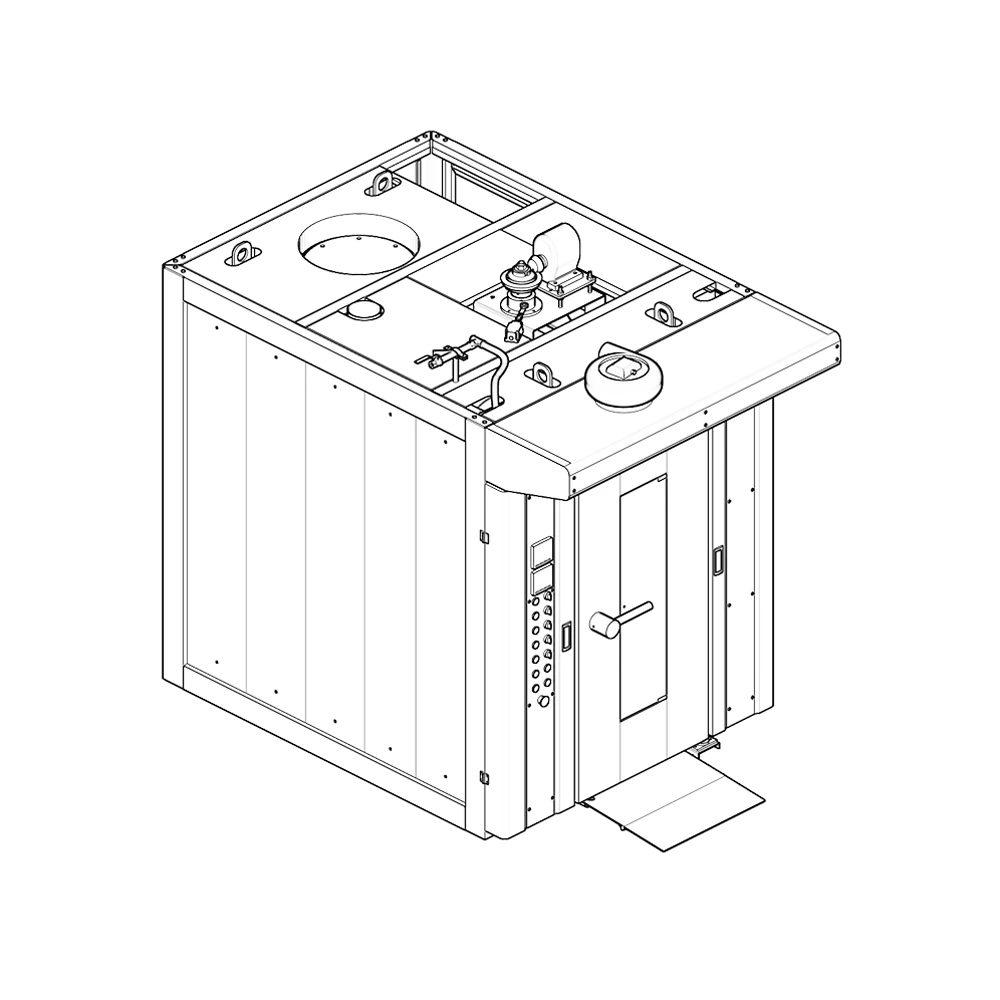

Photos of the Produced MDF 200 :

Introduction to MDF 200 Rotary Rack Ovens

Rotary rack ovens are large-scale baking ovens designed to accommodate multiple baking racks or trays arranged in a circular or rotating configuration. These ovens are known for their versatility, energy efficiency, and ability to produce consistent and high-quality baked goods on a large scale.

Key Components and Mechanisms

- Rotating Rack System: The hallmark feature of rotary rack ovens is their rotating rack system, which allows multiple baking racks or trays to rotate within the oven chamber. This rotation ensures even heat distribution and uniform baking across all trays, resulting in consistent product quality.

- Heat Source: Rotary rack ovens typically utilize either gas or electric heating systems. Gas-fired ovens feature burners that generate heat, while electric ovens use heating elements to produce the required baking temperatures.

- Steam Injection System: Many rotary rack ovens are equipped with steam injection systems that provide controlled bursts of steam during the baking process. Steam helps create a humid baking environment, enhancing crust development, promoting oven spring, and improving the overall texture of baked goods.

- Temperature and Humidity Control: Advanced rotary rack ovens feature precise temperature and humidity control systems, allowing bakers to adjust baking parameters to achieve the desired results for different types of products.

- Insulation and Ventilation: Efficient insulation and ventilation systems are incorporated into rotary rack ovens to minimize heat loss, maintain consistent baking temperatures, and ensure energy efficiency during operation.

Advantages of MDF 200 Rotary Rack Ovens

- Uniform Baking: The rotating rack system in rotary ovens ensures uniform heat distribution and baking across all trays, resulting in consistent product quality and eliminating the need for manual tray rotation.

- High Capacity: Rotary rack ovens are designed to accommodate multiple baking racks or trays, allowing for large batch production of a wide range of baked goods in a single baking cycle.

- Versatility: These ovens are versatile and can handle various types of baked goods, including bread, pastries, cakes, cookies, and more, making them ideal for commercial bakeries and food production facilities with diverse product offerings.

- Efficiency: Rotary rack ovens are known for their energy efficiency, with insulated chambers, precise temperature control, and steam injection systems contributing to reduced energy consumption during baking cycles.

- Time Savings: The high capacity and efficient baking capabilities of rotary rack ovens enable bakeries to streamline production processes, reduce baking times, and meet customer demand more effectively.

- Consistency: With precise temperature and humidity control, rotary rack ovens ensure consistent baking results, allowing bakeries to maintain product quality standards and meet customer expectations consistently.

Applications of MDF 150 Rotary Rack Ovens

Rotary rack ovens are widely used in commercial bakeries, patisseries, hotels, restaurants, and food production facilities for baking a variety of products, including:

- Bread and rolls

- Pastries and croissants

- Cakes and cupcakes

- Cookies and biscuits

- Pizza and flatbreads

Rotary rack ovens are indispensable equipment in the baking industry, offering efficient, high-capacity baking solutions for commercial bakeries and food production facilities. With their advanced features, uniform baking capabilities, and versatility, these ovens play a vital role in ensuring consistent product quality and meeting the demands of today’s bakery market.

Reviews

There are no reviews yet.