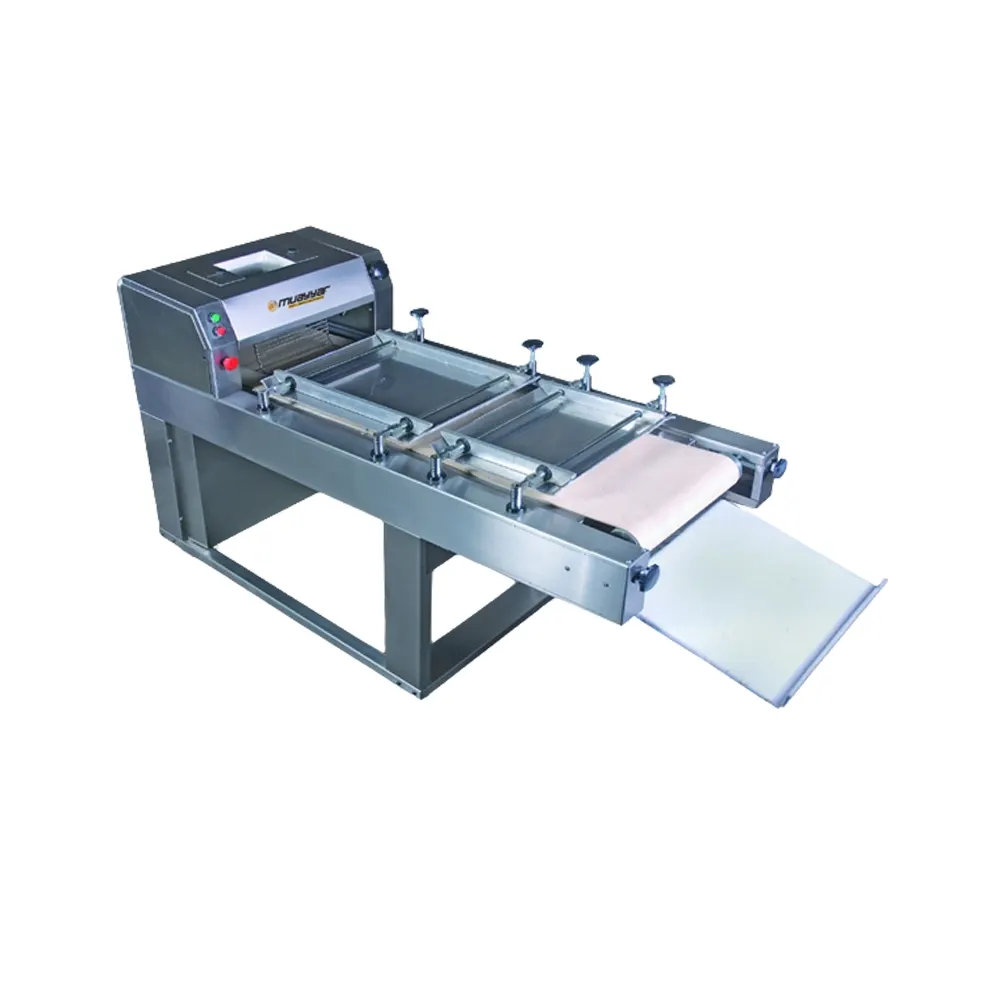

Commercial Dough Moulder Machine

Technicial Specifications

| Model | Unit | MUVM 500 | MUVM 520 |

| Capacity | pieces/hour | 2500 | 2500 |

| Dough Moulding Range | gr | 50 – 1200 | 50 – 1200 |

| Number of Pressing Board | pieces | 2 | 2 |

| Width (W) | mm | 700 | 700 |

| Length (L) | mm | 1950 | 1950 |

| Height (H) | mm | 1100 | 1300 |

| Height of Dough Entrance (H1) | mm | 1100 | 1300 |

| Height of Dough Exit (H2) | mm | 950 | 950 |

| Electrical power | kW | 0,55 | 0,55 |

| Weight of the Machine | kg | 260 | 280 |

Streamlining Bakery Production: The Dough and Bread Moulder Machine

Introduction: In the realm of commercial baking, efficiency and consistency are essential for meeting the demands of consumers and maintaining high-quality standards. The dough moulder machine has emerged as a vital piece of equipment in bakeries, offering precise shaping capabilities and streamlining the dough processing workflow. This detailed article delves into the intricacies of the dough moulder machine, exploring its design, functionality, advantages, and diverse applications in bakery operations.

Understanding Dough and Bread Moulder Machines:

1. Design and Components:

- Dough moulder machines are engineered to shape dough into uniform shapes and sizes for various baked goods such as bread, buns, rolls, and more.

- They typically consist of a conveyor belt system where dough is fed, adjustable rollers or plates that shape the dough, and a discharge conveyor for transferring the molded dough to the next stage of production.

2. Operating Principles:

- Dough is fed into the machine through the conveyor belt, where it passes between adjustable rollers or plates that exert pressure to shape the dough.

- These machines offer flexibility in adjusting the pressure, width, and thickness of the rollers or plates to achieve the desired shape and size of the dough.

3. Key Features:

- Adjustable Parameters:

- Dough moulder machines provide operators with adjustable parameters such as roller pressure, width, and speed, allowing for precise control over the shaping process.

- Versatility:

- They can accommodate various types of dough, including soft and dense dough, enabling bakeries to produce a wide range of baked goods with consistent shapes and sizes.

- High Capacity:

- Many models feature a high-capacity design, capable of handling large volumes of dough to meet the demands of commercial bakery production.

- Ease of Cleaning and Maintenance:

- Removable components and accessible surfaces facilitate easy cleaning and maintenance, ensuring optimal hygiene standards in bakery operations.

Advantages of Dough Moulder Machines:

1. Consistency and Uniformity:

- Dough moulder machines ensure consistent shaping and sizing of dough portions, resulting in uniform baked goods with consistent texture and appearance.

2. Time and Labor Savings:

- Automated shaping reduces the need for manual labor, saving time and labor costs in bakery production.

3. Enhanced Efficiency:

- The streamlined workflow facilitated by dough moulder machines increases production efficiency, allowing bakeries to meet demand without compromising quality.

4. Product Diversification:

- These machines enable bakeries to produce a variety of baked goods with consistent shapes and sizes, expanding their product offerings and catering to diverse consumer preferences.

5. Improved Presentation:

- Uniformly shaped dough portions enhance the visual appeal of baked goods, contributing to a professional presentation and customer satisfaction.

Conclusion: The dough moulder machine has become an indispensable tool in commercial bakery operations, offering precision, efficiency, and versatility in dough shaping. By streamlining the shaping process and ensuring uniformity in dough portions, these machines play a crucial role in optimizing bakery production and meeting the evolving demands of consumers. As the baking industry continues to innovate and evolve, the dough moulder machine remains a cornerstone of efficiency and excellence in bakery operations.

Advanced Features:

- Dough Conditioning:

- Some modern dough moulder machines are equipped with dough conditioning systems that optimize dough consistency and elasticity, ensuring smooth shaping and reducing the risk of dough sticking to the rollers.

- Multi-Functionality:

- Certain models of dough moulder machines offer multi-functionality, allowing them to perform additional tasks such as sheeting, cutting, and decorating dough, thereby streamlining the production process and reducing the need for multiple machines.

- Customization Options:

- Manufacturers may offer customization options for dough moulder machines, including the ability to incorporate specialized attachments or adjust the machine’s configuration to accommodate specific bakery requirements or unique dough characteristics.

- Digital Controls and Monitoring:

- Advanced dough moulder machines feature digital control panels with intuitive interfaces, allowing operators to easily adjust settings and monitor the shaping process in real-time. Integrated sensors and monitoring systems provide feedback on dough consistency and machine performance, enabling proactive maintenance and optimizing production efficiency.

- Energy Efficiency:

- Some modern dough moulder machines are designed with energy-efficient components and technologies, such as variable frequency drives and energy recovery systems, to minimize power consumption and reduce operating costs over the machine’s lifecycle.

Applications in Bakery Production:

- Bread and Rolls:

- Dough moulder machines are commonly used in the production of various types of bread and rolls, including baguettes, sandwich loaves, dinner rolls, and specialty bread.

- Pastries and Croissants:

- These machines are also employed in shaping dough for pastries, croissants, Danish pastries, and other laminated dough products, ensuring consistent shapes and layers for optimal baking results.

- Pizza Dough:

- Dough moulder machines play a crucial role in shaping pizza dough, facilitating the production of evenly sized and shaped pizza bases for both traditional and artisanal pizza varieties.

- Specialty Baked Goods:

- In addition to standard bakery products, dough moulder machines can be used to shape dough for specialty baked goods such as filled pastries, pretzels, bagels, and ethnic bread varieties, offering versatility in bakery production.

Reviews

There are no reviews yet.